Our References

QUALITY FLAVORS....Pakistan SOUTH AFRICA........Isegen Ltd COLOMBIA .... Carboquimica THAILAND ..... SC. Co IRAN ............... Faratav Co PAKISTAN ...... Nimir Chem PAKISTAN ...... A.T.S Group ROMANIA ....... Oltchim UZBEKISTAN........Euroasia UZBEKISTAN........Merit Kimyo TURKEY............ 9 Company UCIC Cable .............. JordanDOTP Plant

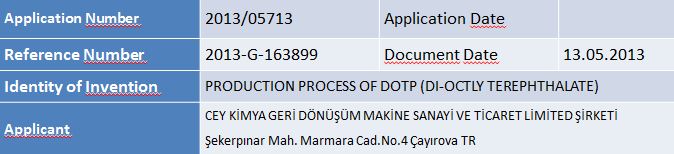

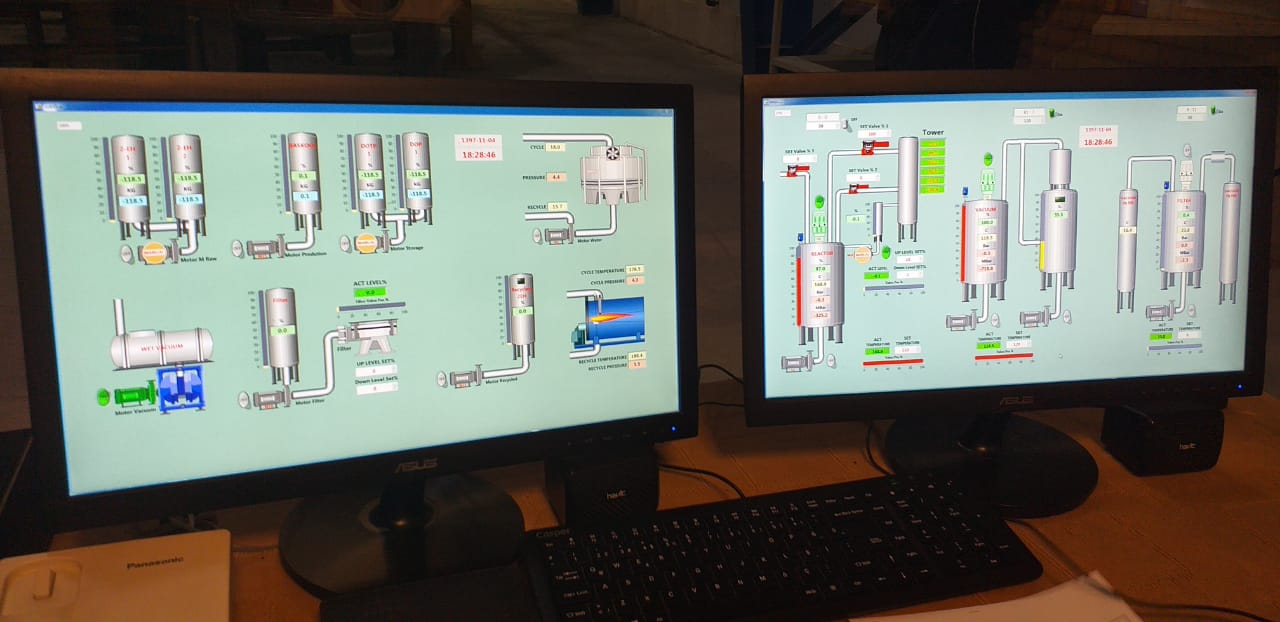

Turn-Key DOTP Plant

Advantages of our Technology

- Reaction temperature is maksimum 225 C

- Reaction takes place in unpressurized, open to atmosphere platform.

- Nitrogen gas is nonutilizable in the reaction.

- The excess alcohol never turns to yellowish, even when it use a hundred times.

- There is no alcohol lost or waste in production.

- Manufactured DOTP colour is always 10 hazen.

- The mud amount resultant is %0,2

Turn-Key DOTP plant

With our patented plasticizer technology, we build the most qualified and economic DOTP (Di Octyl Tere Phthalate) production plants. Through the advantages of our technology, we have built more than 30 turn-key DOTP plants in such a short time. The sum of the capacities of plans we built has reached to 500.000 tons/year.

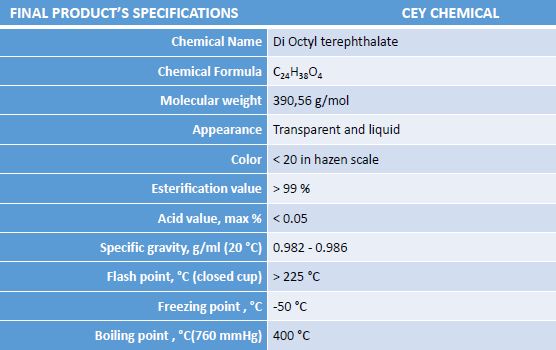

PATENTED DOTP PRODUCTION PROCESS

- Patent application for our production process was made in 13.05.2013.

- Our application successfully passed the examination done by Turkey Patent Office.

- Our application is sent to Russia for international examination.

- Our application successfully passed international examination.

Necessary Raw Materials to Produce 1 Ton DOTP

425 Kg PTA

668 Kg 2EH

2 Kg TIPT

2 Kg NaOH

Waste Materials from 1 Ton DOTP Production

From DOTP reaction 92 KG brilliant, light alcohol scented and residue free waste water comes out. Besides, to wash 1 ton DOTP, 70 kg water is used. Washing water includes less than totally %1 soap, 2EH and DOTP.

There is not any solid waste from DOTP production. Only on the surface of the filter press there is around 1-2 mm DOTP mug.

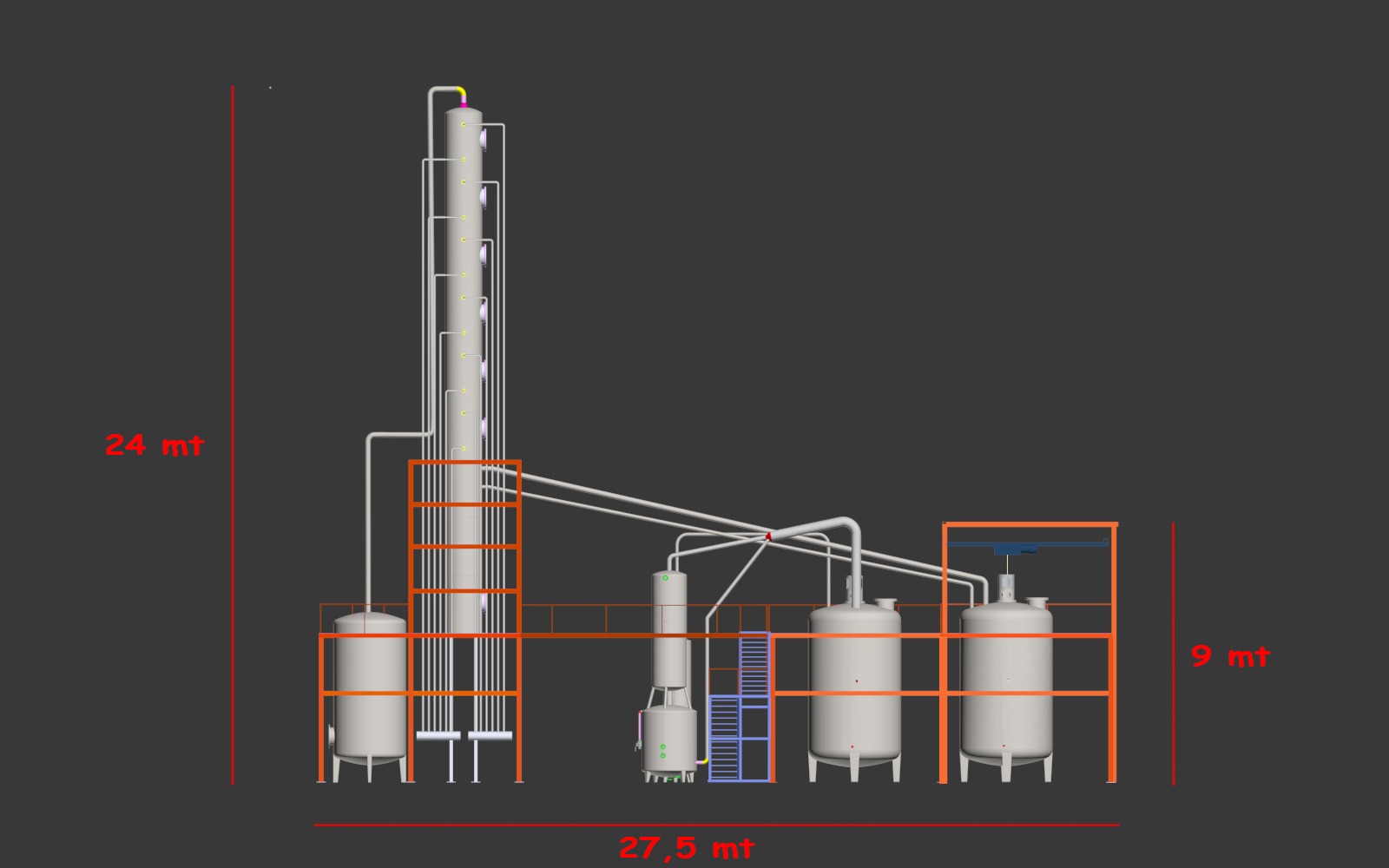

DOTP Production Flow Diagram

DOTP Production

We are building DOTP facilities all over the world.

Why everyone chooses our technology?

As you know, technology is constantly evolving.

There are huge differences between our technology and the old DOTP technology.

For production of 1 ton DOTP, you need

425 Kg PTA + 667 Kg 2EH ------ 1000 Kg DOTP + 92 Kg H2O

But this is teoritical formula.

Practically, in reality

425 Kg PTA + 667 Kg 2EH ------ 1000 Kg (DOTP + DOTP mud + loss + wastage) + 92 H2O

1000 Kg is NOT only DOTP, this amount is total of DOTP, DOTP mud, loss, wastage

Old technologies waste and mud rate were bigger than 3%.

1- In old technologies you get too much DOTP mud.

In our technology, the amount of DOTP mud is very very small.

2- As you know everybody use excess 2EH for DOTP production.

We never lost 1 Kg 2EH in our plant.

But in old DOP plant you lost much amount of 2EH

3- In our technology excess 2EH never turn be yellow.

If You produce each month 1000 tons DOTP with old technology

A loss of 1% in 1000 ton DOTP is even 10 tons of DOTP.

+ More energy

+ More labor cost

As a result ,

You will lost every month minimum 20.000 USD for producing 1000 ton DOTP with old tecnology.

But in our technology YIELD is BIGGER than %99.

1- Can the raw materials be found easily?

You can easily find the raw materials of Plasticisers like DOTP, DOP, and DOA all over the world.

Required raw materials for DOTP: 2EH (2 Ethyl Hexanol), PTA (Terephthalic acid)

Required raw materials for DOP: 2EH (2 Ethyl Hexanol), PA (Phthalic Anhydride)

Required raw materials for DOA: 2EH (2 Ethyl Hexanol), AA (Adipic acid)

2-Can we visit the facilities you set up?

Absolutely Not. Why?

- We are only setting up plasticiser plants. We do not have our own production facilities.

- None of the chemical plants in the world, except for the fact that visiting their plants, they do not even let you to take a picture of the plant.

- The world market is not big anymore. Especially all the companies that producing DOTP exports. Why do they lead theirselves to the establishment of a competitor?

After you have set up your DOTP plant,

- Do you want other companies to produce DOTP?

- Do you help other companies to produce DOTP?

- Would you show someone of your facility?

PLEASE, DO NOT COME TO US WITH SUCH AN OFFER.

3- Could you give information about raw material prices?

Raw material prices vary daily by foreign currency, oil prices and market conditions. According to the prices you get by phone call from a few companies so the feasibility reports will definitely not be right. Because, the raw material selling companies will only tell you the list prices.

4-Can we produce other Plasticizers?

At the DOTP facility, you can produce all plasticizers such as DOP, DOA, DINP, TOTM.

5- Waste from 1 ton DOTP Production

92 kilograms of water will come out of the reaction.

70 kilograms of water will be used to wash a ton of DOTP.

Total waste water amount is 162 kg

* It contains less than %1 impurities (2EH and some soap

* It has light alcohol smell and no color

6- If selling price of DOTP and DOP are same why many companies produce DOP not DOTP in asia and developing countries?

48,000 tons / year capacity plant

.PNG)