Our References

QUALITY FLAVORS....Pakistan SOUTH AFRICA........Isegen Ltd COLOMBIA .... Carboquimica THAILAND ..... SC. Co IRAN ............... Faratav Co PAKISTAN ...... Nimir Chem PAKISTAN ...... A.T.S Group ROMANIA ....... Oltchim UZBEKISTAN........Euroasia UZBEKISTAN........Merit Kimyo TURKEY............ 9 Company UCIC Cable .............. Jordan INDIA...........INDO MEXICO.....Magnecon-KEMEKDOTP Plant

Turn-Key DOTP Plant

Advantages of our Technology

- Reaction time is less than 6 hours.

- Reaction temperature is maksimum 225 C

- Reaction takes place in unpressurized, open to atmosphere platform.

- Nitrogen gas is nonutilizable in the reaction.

- The excess alcohol never turns to yellowish, even when it use a hundred times.

- There is no alcohol lost or waste in production.

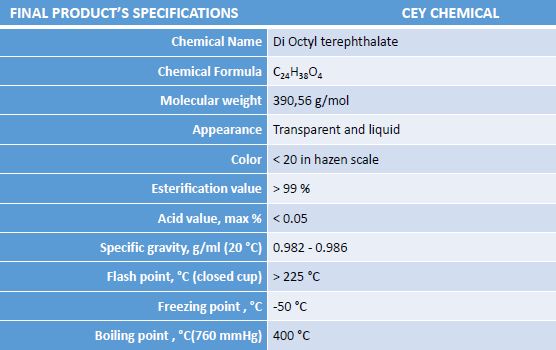

- Manufactured DOTP colour is always 10 hazen.

- The mud amount resultant is %0,2

Turn-Key DOTP plant

With our patented plasticizer technology, we build the most qualified and economic DOTP (Di Octyl Tere Phthalate) production plants. Through the advantages of our technology we have built 11 turn-key DOTP plants in such a short time. The sum of the capacities of plans we built have reached to 200.000 tons/year.

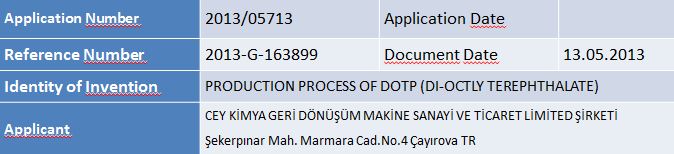

PATENTED DOTP PRODUCTION PROCESS

- Patent application for our production process was made in 13.05.2013.

- Our application successfully passed the examination done by Turkey Patent Office.

- Our application is sent to Russia for international examination.

- Our application successfully passed international examination.

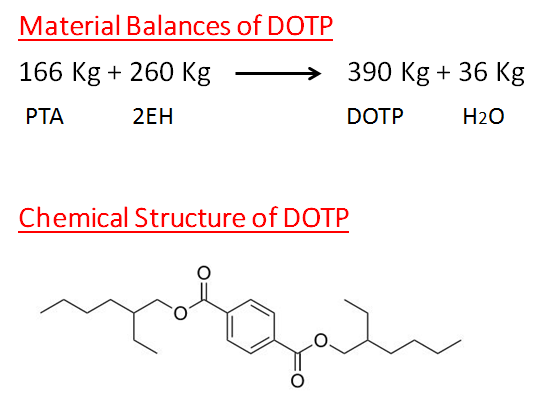

Necessary Raw Materials to Produce 1 Ton DOTP

425 Kg PTA

668 Kg 2EH

2 Kg TIPT

2 Kg NaOH

Waste Materials from 1 Ton DOTP Production

From DOTP reaction 92 KG brilliant, light alcohol scented and residue free waste water comes out. Besides, to wash 1 ton DOTP, 70 kg water is used. Washing water includes less than totally %1 soap, 2EH and DOTP.

There is not any solid waste from DOTP production. Only on the surface of the filter press there is around 1-2 mm DOTP mug.

DOTP Production Flow Diagram